Wheels are not only important for the way your car handles and sits but for the way your car looks. Do you know what to look for when buying wheels?

One of the most important purchases for any vehicle are wheels. Having a bad looking set of wheels on your ride can demean the hours of blood, sweat, and tears you’ve put in to modifying it. Getting the right look for your vehicle takes a lot of time and research, but when it comes down to making the purchase some aren’t willing to dish out the cash for quality.

Someone running replica wheels, in the car world, is like someone going out and buying a pair of pumps with a red sole for under a hundred dollars and trying to pass them off as Louboutin’s. Sure they look good and they match your outfit, but wait until you get them stuck in a crack and that three inch heel breaks off like a Kit-Kat bar. The quality just is not the same.

Wheel companies that offer a quality well rounded wheel charge a hefty sum for their product. Years of research and development have gone in to their products to make them safe and reliable. Even though they look almost identical to the expensive wheels, they are far from it.

What is an alloy wheel?

Alloy wheels are made by forcing a combination of molten aluminum and magnesium into a mold of s wheel’s shape. Cast alloy wheels started coming into production in the 1900’s. The wheels were easy to make, lighter, and had had almost the same durability as the heavier steel wheel.

With years of research and development, easier methods of casting came in to play. Today, there are three main methods to casting wheels: gravity cast, low pressure cast, and high pressure cast.

Gravity is the most cost efficient, but it allows for the forming of air pockets and a greater absorption of impurities from the mold. This allows the retail cost to be the cheapest.

Low pressure casting involves forcing the liquid alloy into the mold using positive pressure giving it the ability to form quicker and fill every nook and cranny inside the mold. The pressure allows the metal to cure quicker make it denser than a gravity cast wheel, making the wheel stronger.

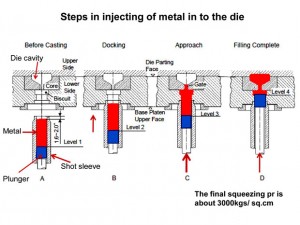

High pressure cast is the same method of production as low pressure cast but only an increase in positive pressure.

Forged wheels are not cast, but it is another method of making a wheel. Forged wheels are cut out of a billet block of aluminum. Starting from an already solid unit means that there is the lowest chance of imperfections in the final product.

With each casting method of casting the quality and strength is increased, along with the price associated with it.

Price can make a huge difference

The cost difference is black and white between the real and the reps. With a quick google search for BBS RS Series wheels you can see that they range anywhere between $1,500 and $2,100 a set depending on the rim size. If you look up replicas, you find STR RS series knock offs selling for $166 a wheel, around $700 for a whole set.

To rep or not to rep

Don’t knock replica wheels just yet. It all comes down to the purpose of use and how they were made. If too much strain is put on a wheel that wasn’t made for that application, you risk breaking spokes or the lip, causing you to lose control of your vehicle.

If you dent one of your stock wheel on your daily driver and you need a replacement, a lot of companies make replicas that look like identical to ones you get from your dealership and are a cheap alternative. If you’re driving a stanced car that will only see the street and your driveway, replicas can be an easy way to make your car look better for a cheaper price. With these applications you could get away with using a gravity cast or low pressure cast wheel.

On the other side of the coin, if you plan on making 600 wheel horse power and participating in drag racing or your local track day, you may want to reconsider.

Cheap replicas, poorly cast replicas, have not had extensive quality control or testing done to make sure they are rigid and can take a beating. This is where they have their downside. If too much force is exerted on the wheel due to high intensity turning, acceleration or breaking, it can cause the center spokes to snap off or the lip to break. This can cause you to lose control resulting in your car ending up on the back of a wrecker.

Small financial sacrifices make big issues disappear

This isn’t to say that you couldn’t get away with doing a track day with high-pressure cast wheels; and you could most definitely do it with a forged wheel. It all boils down to, what you want to do, and if you think the safety of you and your car worth the cash.

Real wheels from a reputable company is always the way to go. But everyone gets it, sometime you just don’t have the cash flow to get the biggest and best.